|

|

|

|

|

|

| |

|

| |

|

|

|

|

|

Fluidnatek_Bioinicia

_Brochure.pdf

FLUIDNATEK_LAB_TOOLS.pdf

FLUIDNATEK_TOOLS_

for_INDUSTRY.pdf

|

|

| BioInicia는 Nano Technology 분야의 선두 기업으로 나노파이버, 나노파티클 관련 연구 및 산업 기기의 디자인 및 생산을 주요 사업으로 하고 있습니다.나노 소재는 각종 첨단전자제품, 전지셀과 같은 에너지 분야, 자동차나 항공기와 같은 수송장치, 인공피부나 약물전달시스템과 같은 바이오 및 제약 기술 분야 제품에 널리 사용될 뿐만 아니라 스포츠 레저용품, 의류제품 등 우리 일상 용품에도 직접 적용되는 첨단 소재입니다.

|

| |

As the engineering division of BioInicia, FLUIDNATEK™ main activity is the design, manufacturing and commercialization of eStretching

(eSpinning and eSpraying) equipment. In our constant chase for customer satisfaction, FLUIDNATEK™ is focused on providing research groups

and companies involved in micro-submicro-nanoparticles and fibers technology with suitable equipment to develop and produce their products at their target scale. Having a temperature and humidity control is a big advantage of Fluidnatek system compared to other eSpray manufactures.

Another important advantage is the Taylor cone visualization.

Both features ensure a much better control on the process, thus ensuring reproducibility of the results.

In addition, BioInicia is willing to share with customers through hosting them in BioInicia office, or having joint projects.

On the other hand, BioInicia's main advantage compared to other manufacturers is the scalability, especially in coaxial.

If there are customers aiming at higher volumes, other manufacturer doesn't have anything to do against Fluidnatek.

|

|

|

|

| |

|

|

|

|

|

| |

| BioInicia는 Nano Technology 분야의 선두 기업으로 나노파이버, 나노파티클 관련 연구 및 산업 기기의 디자인 및 생산을 주요 사업으로 하고 있습니다.나노 소재는 각종 첨단전자제품, 전지셀과 같은 에너지 분야, 자동차나 항공기와 같은 수송장치, 인공피부나 약물전달시스템과 같은 바이오 및 제약 기술 분야 제품에 널리 사용될 뿐만 아니라 스포츠 레저용품, 의류제품 등 우리 일상 용품에도 직접 적용되는 첨단 소재입니다.

|

| |

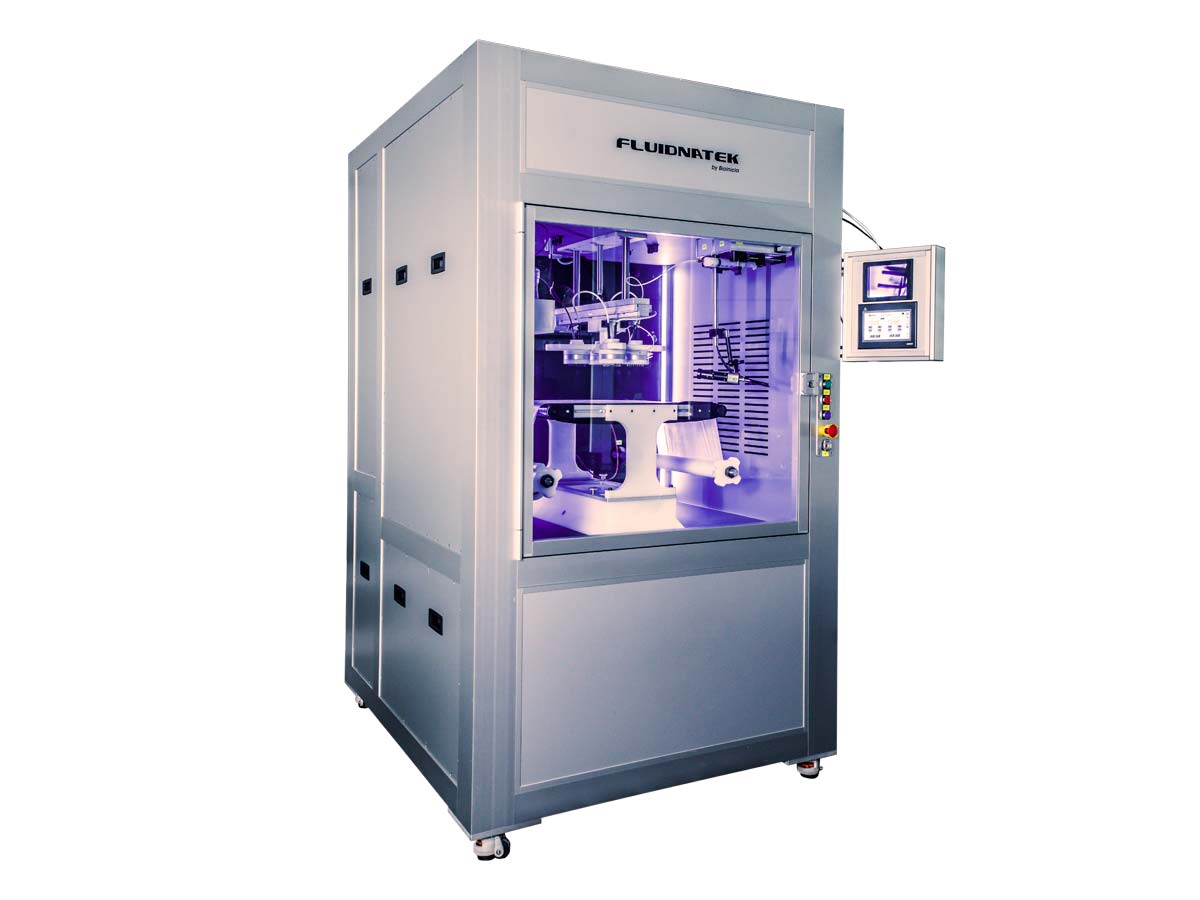

Spinbox is a simple, safe and configurabledevice for your electrospinning or electrospraying activities.

Spinbox is a modular bench-top electrospinning and electrospraying instrument designed for lab-scale fabrication of micro- or nano-structured fibers and particles for use in a wide variety of applications including regenerative medicine, drug delivery, microencapsulation of food or skin-care ingredients, functional textiles, filtration, and many more.

Bioinicia brings its expertise as a leading supplier of premium-quality electrospinning and electrospraying equipment to launch this latest instrument, which offers an ideal platform for materials development, proof-of-concept and teaching purposes.

EASE OF USE

Spinbox has a simple, user-friendly design to enable a quick and intuitive experimental set-up and operation.

This entry-level instrument has been designed to provide an ideal introduction to the electrospinning and electrospraying processes and is suitable for lab-scale materials R&D and proof-of-concept activities. It’s also a great tool for teaching purposes and requires no previous electrospinning experience to get started.

CUSTOMIZABILITY

Spinbox has a modular design allowing it to be easily configured with a wide array of different features and functionalities, which the user can select from to customize the apparatus according to their specific needs. Sealable cable pass-throughs in the chamber wall provide unparalleled flexibility over experimental set-up without compromising on safety.

USER-SAFETY

This simple bench-top electrospinning machine comes with a number of built-in safety features to ensure user-safety is maintained at all times. These include:

-Safety interlocked spinning chamber

-Electrically grounded chamber to prevent accumulation of electrostatic charge

-External control of all parameters via touch-control interface or computer

-Exhaust fan to extract solvent vapor

-CE marked

QUALITY DESIGN AND CONSTRUCTION

Spinbox is constructed from high-quality solvent-resistant materials and tried-and-tested components to ensure reliability and long-lasting durability. Glass chamber walls and diffuse LED lighting provide an uncompromised view of the electrospinning jet.

THE BEST SOLUTION FOR COST-SENSITIVE BUDGETS

This budget-conscious tool enables you to carry out high-quality materials R&D, and lab-scale proof-of-concept projects with only a small investment.

POWERED BY BIOINICIA

Bioinicia has used its experience in the design of its premium-quality Fluidnatek® range of lab- and pilot-scale electrospinning equipment and GMP-certified pharmaceutical manufacturing plant to develop the new entry-level Spinbox platform ? offering a simple and reliable tool to meet your electrospinning research needs for a budget-friendly price. If, in the future, you need more advanced functionality or larger scale production, Bioinicia has the solutions to suit and your Spinbox developments can simply be transferred.

Materials: The chamber is made of solvent resistant materials, i.e. anodized aluminium, high-performance plastics, powder coated steel and glass

Non-regulated exhaust system to properly exhaust evaporated solvents. Fitted with port to allow connection to external ventilation via a 50 mm ID duct

Embedded diffuse led lighting for proper process visualization

Sealed cable pass-throughs: Tubing, power and/or control wires can be easily wired out from the chamber, enabling the users to improve the experimental set-up by the installation of additional accessories

Horizontal and vertical electrospinning. Regulation of emitter-collector distance from 50 to 250mm

Safety interlocked door system with opening safety detection

Dimensions: External: 500mm width x 550mm depth x 532mm height. Internal: 495mm width x 430mm depth x 373mm height

Safety features: CE compliant, fulfilling all the corresponding EU Directives (2006/42/EC, 2004/108/EC, 2006/95/EC). Verified by independent 3rd Party

|

|

|

|

| |

|

|

|

|

|

| |

| BioInicia는 Nano Technology 분야의 선두 기업으로 나노파이버, 나노파티클 관련 연구 및 산업 기기의 디자인 및 생산을 주요 사업으로 하고 있습니다.나노 소재는 각종 첨단전자제품, 전지셀과 같은 에너지 분야, 자동차나 항공기와 같은 수송장치, 인공피부나 약물전달시스템과 같은 바이오 및 제약 기술 분야 제품에 널리 사용될 뿐만 아니라 스포츠 레저용품, 의류제품 등 우리 일상 용품에도 직접 적용되는 첨단 소재입니다.

|

| |

The Fluidnatek LE-50 is a compact laboratory benchtop machine as powerful as an advanced research station. Designed with adaptability in mind, the highly modular LE-50 electrospinning device can be easily configured for a variety of electrospinning or electrospraying tasks. Crucially, it is compatible with an AC unit for climate control, which can be added at any time, making it an ideal machine for conducting precise research or development activities. All Fluidnatek electrospinning equipment is compatible all along the range of machines for doing the scale up from lab stage to manufacturing.

Selected specs and features:

Compact design for small laboratory spaces

Easily configured for variety of tasks

Advanced electrospinning machine with hygienic design

Solvent resistant for effective cleaning and cleanroom compatibility

Touch control interface with data logging multi user-level access

Coaxial electrospinning configuration

Exchangeable rotating collectors with scanning motion emitter

Optional second independent spinning stage for processing two materials at the samel time

Compatible AC bench unit for temperature and humidity control

Extraction fan to exhaust solvent vapours

Safety interlock

CE certified and UL compatible

Machine Qualification package available to enable GMP or ISO13485 process validation

|

|

|

|

| |

|

|

|

|

|

| |

| BioInicia는 Nano Technology 분야의 선두 기업으로 나노파이버, 나노파티클 관련 연구 및 산업 기기의 디자인 및 생산을 주요 사업으로 하고 있습니다.나노 소재는 각종 첨단전자제품, 전지셀과 같은 에너지 분야, 자동차나 항공기와 같은 수송장치, 인공피부나 약물전달시스템과 같은 바이오 및 제약 기술 분야 제품에 널리 사용될 뿐만 아니라 스포츠 레저용품, 의류제품 등 우리 일상 용품에도 직접 적용되는 첨단 소재입니다.

|

| |

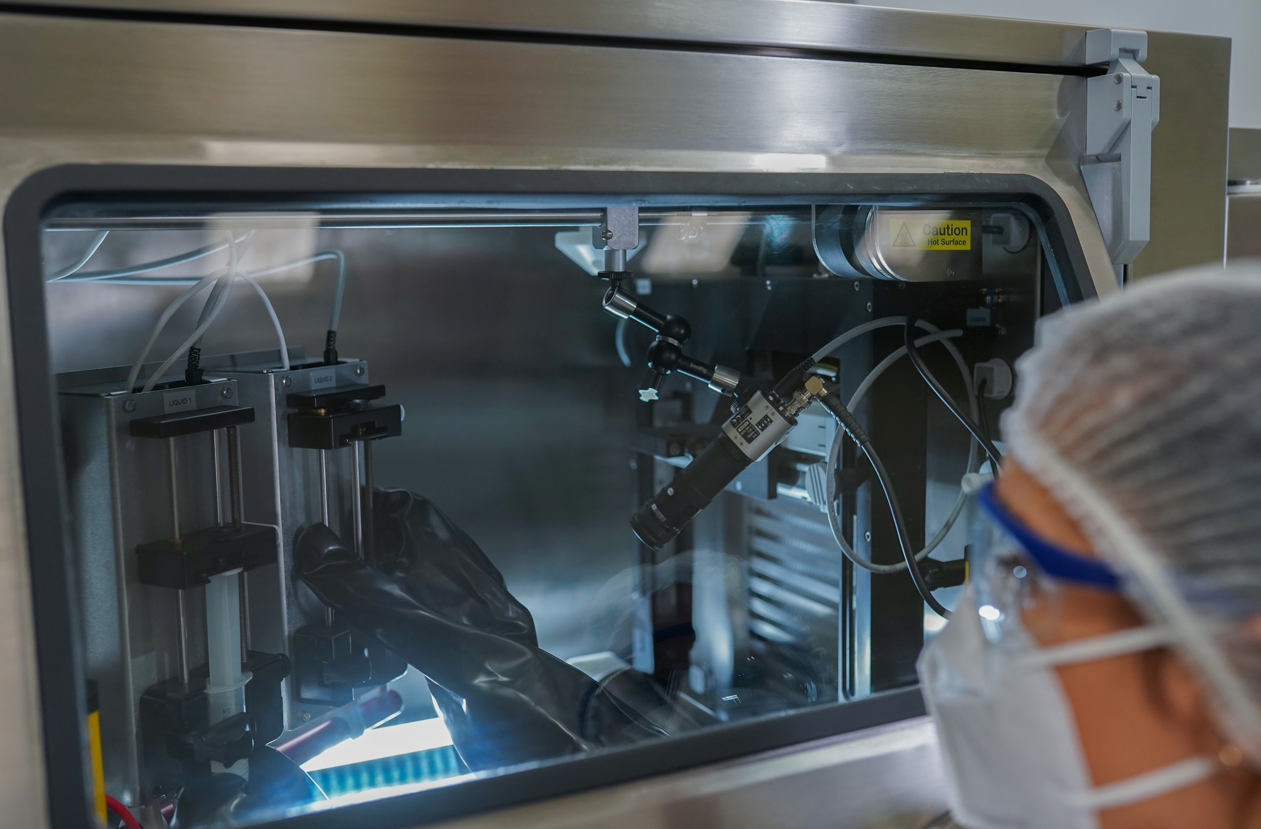

The electrospinning machine Fluidnatek LE-100 is an advanced R&D too with the flexibility to suit even the most advanced electrospinning or electrospraying projects. With a large expermental chamber and wide range of optional features, the LE-100 is an electrospinning apparatus which can be adapted to any task. Crucially, it is compatible with an AC unit for climate control, which can be added at any time, making it an ideal machine for conducting precise research, development, or small-scale production activities. Ideal electrospinning equipment for advanced research, extremely flexible for carrying out all kind of experimental arrangements and able to be equipped with non- conventional advanced features.

Selected specs and features:

Equipment choice for advanced development projects

Large experimental chamber for flexible configuration

Ultimate control of all processing parameters

Ultra-advanced electrospinning device with hygienic design

Actively regulated exhaust system with pressure sensing

Coaxial electrospinning configuration (or even tri-axial)

Solvent resistant for effective cleaning and cleanroom compatibility

Touch control interface with data logging multi user-level access

Up to 20 emitters for increased productivity

Programmable X, Y and Z axes motion for patterned deposition

Exchangeable rotating collectors with scanning motion emitter

Optional second spinning stage for processing two materials at the same time

Compatible AC unit for temperature and humidity control

Safety interlock

CE certified and UL compatible

Machine Qualification package available to enable GMP or ISO13485 process validation

|

|

|

|

| |

|

|

|

|

|

Technical_Datasheet_LE_500.pdf

FLUIDNATEK_TOOLS_

for_INDUSTRY.pdf

|

|

BioInicia는 Nano Technology 분야의 선두 기업으로 나노파이버, 나노파티클 관련 연구 및 산업 기기의 디자인 및 생산을 주요 사업으로 하고 있습니다.나노 소재는 각종 첨단전자제품, 전지셀과 같은 에너지 분야, 자동차나 항공기와 같은 수송장치, 인공피부나 약물전달시스템과 같은 바이오 및 제약 기술 분야 제품에 널리 사용될 뿐만 아니라 스포츠 레저용품, 의류제품 등 우리 일상 용품에도 직접 적용되는 첨단 소재입니다.

관련 분야 최초 연구용 및 산업용 듀얼 모드로 선택 사용 가능한 전기 방사 시스템 LE-500 탄생!!

|

| |

The Fluidnatek LE-500 is an electrospinning machine conceived to be pilot-line production tool that provides all of the capability needed to develop a product from initial concept to pilot-scale manufacture. With roll-to-roll collection, large-volume solution reservoirs, and high-throughput multi-emitter spinning heads, the LE-500 is the ideal electrospinning equipment for fabrication of pre-production volumes of production-quality materials. However, the LE-500 can be run either in R&D mode or in manufacturing mode, that way being a flexible electrospinning device as well.

LE-500 is pilot e-spinning tool provided by BioInicia.

It has two operation modes: lab mode, with only one nozzle and in production mode, with up to 96 emitters.

This unit is unique in the market, for its dual operation and for the ability of upscaling coaxial eSpinning.

Selected specs and features:

Configurable for R&D and / or pilot-scale production

Pilot-production plant with hygienic design

Exchangeable rotationg collectors and roll-to-roll with scanning motion emitters

Multi-emitter spinning heads for high-throughput electrospinning or electrospraying

Configuration for coaxial electrospinning (or even tri-axial)

Large-volume solution feeding system for extended production batches (single-phase or coaxial)

Solvent resistant for effective cleaning and cleanroom compatibility

Touch control interface with data logging and multi user-level access

Compatible AC unit for temperature and humidity control

Electrospinning apparatus equipped with actively regulated exhaust system preventing the solvent vapours to escape even with the door opened

Safety interlock

CE certified and UL compatible

Machine Qualification package available to enable GMP or ISO13485 process validation

|

|

|

|

| |

|

|

|

|

|

| |

| BioInicia는 Nano Technology 분야의 선두 기업으로 나노파이버, 나노파티클 관련 연구 및 산업 기기의 디자인 및 생산을 주요 사업으로 하고 있습니다.나노 소재는 각종 첨단전자제품, 전지셀과 같은 에너지 분야, 자동차나 항공기와 같은 수송장치, 인공피부나 약물전달시스템과 같은 바이오 및 제약 기술 분야 제품에 널리 사용될 뿐만 아니라 스포츠 레저용품, 의류제품 등 우리 일상 용품에도 직접 적용되는 첨단 소재입니다.

|

| |

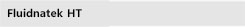

Industrial Electrospinning Machine

The Equipment of Choice for Industrial Manufacturing and Commercialization

The Fluitnatek HT Industrial Electrospinning Machine is the ideal industrial equipment when large scale production and sample reproducibility are needed. This industrial electrospinning line capitalizes on the know-how and experience in the field of materials processing by Bioinicia.

Industrial Electrospinning Machine Features

The Fluidnatek HT provides state-of-the-art features for industrial scale production and commercialization of electrospun products under GMP and reproducible performance. This equipment offers the capability to use 5,500+ simultaneous needles, a 1.6 meter wide roll substrate, up to 50 L of solution, and tightly control temperature and relative humidity with its environmental control unit (ECU) for batch-to-batch consistency. Some of the safety features include an actively regulated exhaust system to remove solvents continuously and dynamically, along with preventing them from escaping the spinning chamber. If flammable solvents are to be used, the Fluidnatek HT allows you to work under an inert atmosphere (with very low oxygen concentration) to further increase safety aspects to the user and the facility.

Selected Standard Features:

-Industrial scale production unit for product commercialization

-Industrial Roll-to-Roll system

-Touchscreen controls

-Bottom-up configuration

-Primary high voltage power supply for the emitter

-Secondary high voltage power supply for the collector

-Gravimetric controlled continuous solution feeding system

-10 kg/h+ solution mass flow rate (solution dependent)

-Non-spill quick connectors

-Environmental Control Unit ECU (temperature and relative humidity)

-Single-phase multi-emitter spinning head

-Safety shut-off switches in the access door

-Actively regulated exhaust system

Optional Upgradeable Features:

-Sample thickness measurement in real time

-Gas and solvent vapor-assisted processing

-Engineered accessories to meet application requirements

-Secondary spinning stage with independent power supply

|

|

|

|

| |

|

|

|

|

|

Fluidnatek LE-50 ProSterile_brochure.pdf

| |

BioInicia는 Nano Technology 분야의 선두 기업으로 나노파이버, 나노파티클 관련 연구 및 산업 기기의 디자인 및 생산을 주요 사업으로 하고 있습니다.나노 소재는 각종 첨단전자제품, 전지셀과 같은 에너지 분야, 자동차나 항공기와 같은 수송장치, 인공피부나 약물전달시스템과 같은 바이오 및 제약 기술 분야 제품에 널리 사용될 뿐만 아니라 스포츠 레저용품, 의류제품 등 우리 일상 용품에도 직접 적용되는 첨단 소재입니다.

멸균 전기방사 제품을 생성 작업이 가능하도록 여러 멸균 기술을 적용하여 챔버에 무균 대기를 생성하도록 특별히 설계된 전용 플랫폼

|

| |

|

|

|

The Only Electrospinning System Equipped for Sterile Development of Medical Products

Ideal for biomedical companies requiring aseptic sample development for medical products under ISO-5 environment, cGMP, and ISO-13485 certification standards.

Features

The Fluidnatek LE-50 ProSterile is the instrument of choice for in-line aseptic electrospun bioprocesses, and medical device manufacturing of sterile products. This system has elevated the electrospinning technique into a new era of ultra-clean medical device processing. The LE-50 ProSterile is the first electrospinning system to offer a fully sterile process environment, enabled by its welded stainless steel interior and exterior, HEPA filtration to meet ISO-5/Class 100 cleanliness standards, and a chamber sterilization system. Glove port access allows sample handling and packaging under sterile conditions, and the vacuum antechamber removes possible traces of solvents while maintaining an exceptional standard of sterility and cleanliness. An environmental control unit (ECU) enables precision control of temperature (20-45°C), and relative humidity (10-80%) to maintain batch-to-batch reproducibility for perfect nanofibers, every time.

Selected Standard Features

-Touch screen controls

-Primary and negative HV power supply

-Syringe pumps

-Active exhaust system

-Rotating collector platform

-High-definition process data hub

-ISO-5 cleanliness

-Glove box port

-Sterilization system

-Vacuum antechamber

-Environmental control unit

Optional Upgradeable Features

-Taylor cone visualization system

-Multi-needle system

-Slit-emitter

-IQ/OQ Documentation

-Secondary HV power supply

|

|

|

|

| |

|

|

|

|

|

| |

BioInicia는 Nano Technology 분야의 선두 기업으로 나노파이버, 나노파티클 관련 연구 및 산업 기기의 디자인 및 생산을 주요 사업으로 하고 있습니다.나노 소재는 각종 첨단전자제품, 전지셀과 같은 에너지 분야, 자동차나 항공기와 같은 수송장치, 인공피부나 약물전달시스템과 같은 바이오 및 제약 기술 분야 제품에 널리 사용될 뿐만 아니라 스포츠 레저용품, 의류제품 등 우리 일상 용품에도 직접 적용되는 첨단 소재입니다.

챔버에서 ISO 5 (Class 100) 달성이 가능한 스테인리스 스틸로 만들어진 특수 FI플랫폼

|

| |

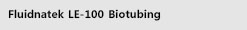

Uniquely Designed for Electrospinning Tubular Medical Products Under Sterile Conditions

The ideal electrospinning system for biomedical companies that need to coat stents, or fabricate vascular grafts, heart valves, and other tubular structures in an environment that meets standards for an ISO-7 environment, cGMP, or ISO-13485 certification.

Features

The Fluidnatek LE-100 Biotubing electrospinning system was carefully designed to maintain sterile processing conditions for tubular medical device manufacturing. This unique system utilizes HEPA filtration to meet ISO-7/Class 10,000 cleanliness standards, and is constructed from materials that support easy sterilization. The LE-100 Biotubing also offers a longer sample development than the standard LE-100 model, and features a quick-release, tensioned rotating collector platform for thin diameter mandrels (1-5 mm) to efficiently exchange collectors and minimize user handling time. A rear pin electrode further improves the electrostatic field, enhancing sample deposition and uniformity. An environmental control unit (ECU) ensures precise control over the temperature (18-45°C), relative humidity (10-80%), and air flow (90-180 m3/h) during processing for perfect nanofibers, every time.

Selected Standard Features

-Touch screen controls

-Primary and negative HV power supply

-Traverse rear pin electrode

-Twin-channel syringe pump

-Active exhaust system

-Rotating collector platform

-X-axis automated scanning emitter motion

-Data logging and export function

-Advanced recipe option

-Environmental control unit

Optional Upgradeable Features

-Second twin-channel syringe pump

-Solvent-gas-jacket system

-Slit-emitter

-IQ/OQ Documentation

-Audit trail function

-Batch control function

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|